Brake-Line Kit

REAR MCH 282 H1

Important notes

Brake-Line Kit REAR MCH 282 H1

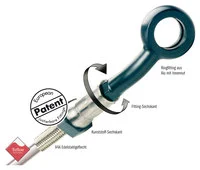

Safety, durability, optimised braking - TRW brake lines for the rear brake are steel-braided hoses which combine exactly these key characteristics. These brake lines are an intelligent solution made in Germany.

- The connections of the steel-braided lines are rotatable

- The steel-braided lines have a transparent sheath

- Marked improvement of the brake's pressure point and response

- The standard colour of the connections is titanium

- The steel-braided lines come as a complete set for each axle

- Longer brake fluid change interval is possible

- The steel-braided lines come complete with seals/gaskets. You will need to order the banjo bolts separately (see Recommendations for this product)

- With type approval in Germany: the brake lines are marked with a KBA (German Motor Transport Authority) number

By the way,

TRW is Germany's market leader for steel-braided brake lines, and gives a long-term guarantee on materials and workmanship. Each line carries a registered serial number and the manufacturer's code.

Please note: You can find installation instructions and the type approval for Germany in the "Documents" section. They can be viewed or printed out in pdf format.

Installation instructions:

Some motorcycles have a permanently welded distributor as standard. It cannot be used if you install steel-braided brake lines. For these models, we supply a two-piece kit, which enables two lines to be secured to the hand-pump by means of the double banjo bolt supplied.

List of compatible motorcycles

TRW Lucas has been manufacturing premium-quality motorbike spare parts since 1976 (ISO 9001, ISO/TS 16949) and is the German market leader for brake discs, brake pads and steel-braided lines. Every time that product tests have been carried out by trade publications over the past 30 years, they have confirmed the excellent quality of these products. They have won test after test. Every second counts when you brake! Don't settle for anything less than quality products from the market leader.

By purchasing this item you have chosen a premium-quality product with superior German workmanship. This internationally acknowledged mark of quality means that this product is the result of efficiently coordinated development and production processes, technological expertise, continuous quality controls.

Accessories with an ABE do not have to be registered in the vehicle documents. However, if you do not want to carry the certificate with you at all times, you can have it registered (at a charge) by the TÜV, for example.

If the accessories are to be used on a vehicle that is not listed in the ABE, an individual approval is necessary.

The regulations in other countries may differ. Before ordering a product, please make sure that it may be used in road traffic in your region, your country.

.

MAINTENANCE:

Stainless steel should be cleaned regularly like all other materials, especially after exposure to salty air (near the coast), and also at regular intervals.

Water can easily collect in corners, edges and screw connections, resulting in corrosion. So careful cleaning is important, and if necessary screws should be undone in order to clean the parts thoroughly.

Do not leave rusty steel parts against stainless steel to avoid the rust "contamination".

To ensure that your objective and truthful report will be really beneficial to all readers, please observe the following rules.

- Please only rate products that you have personally used for their intended purpose.

- Please give reasons for your positive and negative criticisms. Only then will they benefit other customers and allow us to improve the product if necessary.

- Please don’t copy content that has already been published elsewhere. It’s your personal experience which counts.

- Data protection: Please don’t include your own and other people’s addresses, telephone numbers or URLs or even the names of third parties (people as well as companies) in your review.

- In your product review, please don’t make comparisons with third party product ranges. Regardless of whether you judge these positively or negatively, you, or we as operators of this online shop, would be violating competition law.

Fair play: Please follow these rules so that we don’t have to shorten or delete your rating.

Your product rating has been saved. It will be displayed in a few minutes

Do you really want to cancel your entry?